Yc-8101a Sekoahelo sa Ceramic se sa khomareleng sa Porcelain Nano-composite (Se setšo) sa mocheso o phahameng

Likarolo tsa sehlahisoa le ponahalo

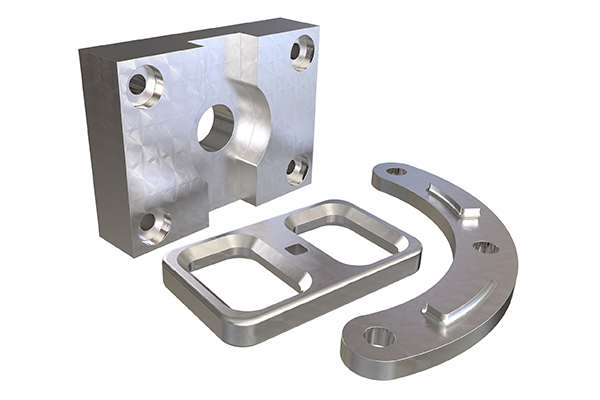

(Seaparo sa letsopa sa likarolo tse peli)

YC-8101A-A:Seaparo sa Karolo ea A

YC-8101A-B: Moemeli oa ho phekola karolo ea B

Mebala ea YC-8101:bonaletsang, bofubedu, bosehla, boputsoa, bosweu, jj. Tokiso ya mmala e ka etswa ho latela ditlhoko tsa bareki

Substrate e sebetsang

Libaka tse fapaneng tsa substrate tse kang lipane tse sa khomareleng li ka etsoa ka tšepe, tšepe e bonolo, tšepe ea khabone, tšepe e sa hloekang, motsoako oa aluminium, motsoako oa titanium, tšepe ea motsoako oa mocheso o phahameng, khalase ea microcrystalline, liserami le li-alloy tse ling.

Mocheso o sebetsang

- Khanyetso e phahameng ka ho fetisisa ea mocheso ke 800℃, 'me mocheso oa ts'ebetso oa nako e telele o ka hare ho 600℃. E hanela khoholeho e tobileng ke malakabe kapa phallo ea khase ea mocheso o phahameng.

- Ho hanyetsa mocheso oa seaparo ho tla fapana ho latela ho hanyetsa mocheso oa li-substrate tse fapaneng. Ho hanela serame le ho thothomela ha mocheso le ho thothomela ha mocheso.

Likarolo tsa sehlahisoa

- 1. Li-nano-coatings li thehiloe metsing feela, li bolokehile, li mosa tikolohong ebile ha li na chefo.

- 2. Liserame tse nang le motsoako o monyane li fumana vitrification e teteaneng le e boreleli mochesong o tlase oa 250℃, e leng se bolokang matla le se khahlisang botle.

- 3. Khanyetso ea lik'hemik'hale: Khanyetso ea mocheso, khanyetso ea asiti, khanyetso ea alkali, ho thibela mocheso, khanyetso ea mocheso o phahameng, le khanyetso ea lihlahisoa tsa lik'hemik'hale, jj.

- 4. Seaparo se hanela mocheso o phahameng le ho thothomela ha mocheso ka har'a botenya bo itseng (hoo e ka bang di-micron tse 30), 'me se na le khanyetso e ntle ea ho thothomela ha mocheso (se hanela phapanyetsano ea mocheso, 'me ha se petsohe kapa ho taboha nakong ea bophelo ba tšebeletso ea seaparo).

- 5. Seaparo sa nano-inorganic se teteaneng mme se na le ts'ebetso e tsitsitseng ea ho thibela motlakase, ka motlakase o mamellang ho thibela mocheso oa li-volts tse ka bang 1000.

- 6. E na le conductivity e tsitsitseng le e ntle ea mocheso le matla a matle a ho kopanya.

- 7. Bothata: 9H, bo hanela malakabe a bulehileng le mocheso o phahameng ho fihlela ho likhato tse 400, bo benyang haholo, le ho hanyetsa ho tsofala ho hoholo

Masimo a kopo

1. Likarolo tsa boiler, liphaephe, li-valve, li-heat exchanger, li-radiator;

2. Khalase e nyenyane e kang kristale, disebediswa le disebediswa, disebediswa tsa bongaka, disebediswa tsa meriana, le disebediswa tsa lefutso la baeloji;

3. Lisebelisoa tsa mocheso o phahameng le likarolo tsa sensor tsa mocheso o phahameng;

4. Libaka tsa lisebelisoa tsa tšepe, hlobo le lisebelisoa tsa ho lahla;

5. Lisebelisoa tsa motlakase tse futhumatsang, litanka le mabokose;

6. Lisebelisoa tse nyane tsa ntlo, lisebelisoa tsa kichine, jj.

7. Likarolo tse nang le mocheso o phahameng bakeng sa liindasteri tsa lik'hemik'hale le tsa tšepe.

Mokhoa oa tšebeliso

(Ho netefatsa liphetho tse ntle, ho kgothaletswa ho e sebedisa ka tsela e latelang)

1. Likarolo tse peli:Koala 'me u phekole ka karolelano ea boima ba 2:1 ka lihora tse 2 ho isa ho tse 3. Seaparo se phekotsoeng se sefshoa ka skrine ea sefe ea li-mesh tse 400. Seaparo se sefshoang se fetoha seaparo sa ceramic se felileng sa nano-composite 'me se behelloa ka thoko bakeng sa tšebeliso ea hamorao. Pente e setseng e lokela ho sebelisoa nakong ea lihora tse 24; ho seng joalo, ts'ebetso ea eona e tla fokotseha kapa ea tiea.

2. Ho hlwekisa thepa ya motheo:Ho tlosa mafura le ho tlosa mafome, ho omisa bokaholimo le ho qhaqha lehlabathe, ho qhaqha lehlabathe ka tekanyo ea Sa2.5 kapa ho feta, phello e ntle ka ho fetisisa e finyelloa ka ho qhaqha lehlabathe ka corundum e tšoeu ea 46-mesh.

3. Mocheso oa ho baka: 270℃ metsotso e 30 (E ka phekoloa mochesong oa kamore. Tshebetso ea pele e fokola hanyane, empa e ka khutlela setloaeling ha nako e ntse e ea.)

4. Mokhoa oa kaho Ho fafatsa:Sesebediswa se lokelang ho fafatswa se lokela ho futhumatswa ho fihlela mochesong o ka bang 40℃ pele se fafatswa; ho seng jwalo, ho ka nna ha eba le ho tetebela kapa ho fokotseha. Ho kgothaletswa hore botenya ba ho fafatsa bo be ka hare ho di-micron tse 30. Se ka fafatswa hanngoe feela.

5. Kalafo ea lisebelisoa tsa ho roala le kalafo ea ho roala

Ho sebetsana le lisebelisoa tsa ho roala: Hloekisa hantle ka ethanol e sa keneng metsi, e omise ka moea o hatelletsoeng ebe u e boloka.

6. Kalafo ea ho roala: Kamora ho fafatsa, e tlohele e ome ka tlhaho holim'a metsi metsotso e ka bang 30. Ebe u e beha ka ontong e besitsoeng likhatong tse 250 'me u e boloke e futhumetse metsotso e 30. Kamora ho e pholile, e ntše.

E ikhethang ho Youcai

1. Botsitso ba tekheniki

Kamora liteko tse matla, ts'ebetso ea theknoloji ea nanocomposite ceramic ea sehlopha sa lifofane e lula e tsitsitse tlas'a maemo a feteletseng, e hanela mocheso o phahameng, ho tšoha ha mocheso le ho bola ha lik'hemik'hale.

2. Theknoloji ea ho hasana ha Nano

Ts'ebetso e ikhethang ea ho hasana e netefatsa hore li-nanoparticles li ajoa ka ho lekana ka har'a sekoahelo, ho qoba ho kopana. Kalafo e sebetsang ea sebopeho e ntlafatsa khokahano lipakeng tsa likaroloana, e ntlafatsa matla a khokahano lipakeng tsa sekoahelo le substrate hammoho le ts'ebetso ka kakaretso.

3. Ho laola ho koahela

Mekhoa e nepahetseng le mekhoa e kopaneng e nolofalletsa ts'ebetso ea ho roala hore e fetoloe, joalo ka ho thatafala, ho hanyetsa ho tsofala le botsitso ba mocheso, ho fihlela litlhoko tsa lits'ebetso tse fapaneng.

4. Litšobotsi tsa sebopeho sa micro-nano:

Dikaroloana tsa letsopa tse nang le nanocomposite di phuthela dikarolwana tsa micrometer, di tlatsa dikgeo, di etsa lesira le teteaneng, mme di eketsa ho ba bonyenyane le ho hanyetsa mafome. Ho sa le jwalo, dikarolwana tse nyane di kenella hodima karolo e ka tlase ya substrate, di etsa mokgahlelo wa tshepe le ceramic, o eketsang matla a ho kopanya le matla ka kakaretso.

Molao-motheo oa lipatlisiso le nts'etsopele

1. Bothata ba ho bapisa katoloso ea mocheso:Li-coefficient tsa katoloso ea mocheso tsa tšepe le thepa ea ceramic hangata lia fapana nakong ea lits'ebetso tsa ho futhumatsa le ho pholisa. Sena se ka lebisa ho thehoeng ha mapetso a manyane ka har'a sekoahelo nakong ea ts'ebetso ea potoloho ea mocheso, kapa esita le ho petsoha. Ho rarolla bothata bona, Youcai o hlahisitse lisebelisoa tse ncha tsa ho roala tseo coefficient ea katoloso ea mocheso e leng haufi le ea substrate ea tšepe, ka hona e fokotsa khatello ea mocheso.

2. Ho hanyetsa ho thothomela ha mocheso le ho thothomela ha mocheso: Ha sekoahelo sa tšepe se fetoha ka potlako pakeng tsa mocheso o phahameng le o tlase, se tlameha ho khona ho mamella khatello ea mocheso e hlahisoang ntle le tšenyo. Sena se hloka hore sekoahelo se be le khanyetso e ntle ea ho thothomela ha mocheso. Ka ho ntlafatsa sebopeho sa microstructure sa sekoahelo, joalo ka ho eketsa palo ea li-interface tsa mekhahlelo le ho fokotsa boholo ba lijo-thollo, Youcai e ka ntlafatsa khanyetso ea eona ea ho thothomela ha mocheso.

3. Matla a ho kopanya: Matla a ho kopanya pakeng tsa ho roala le substrate ea tšepe a bohlokoa bakeng sa botsitso ba nako e telele le ho tšoarella ha ho roala. Ho ntlafatsa matla a ho kopanya, Youcai o hlahisa lera le mahareng kapa lera la phetoho pakeng tsa ho roala le substrate ho ntlafatsa ho koloba le ho kopanya lik'hemik'hale pakeng tsa tse peli.